Amazon FreeRTOS sample code includes STM32L4 Discovery kit IoT node (B-L475E-IOT01A board), for compilation of which you need to install System Workbench for STM32, an Eclipse based IDE. However it can be avoided if you can build Makefile based environment with following steps.

(download source) Download the source code from Amazon and expand it into the directory of your choice, say AmazonFreeRTOS. It has three directories as explained in the directories.txt file.

(collect user folders) User files are in the two common directories under the demos.

Create a project directory, say aws_demos, create src subdirectory, and copy all the directories under two common directories into src.

(project root files) Populate the root folder of the project with following files:

- Makefile

- startup_stm32l475xx.s (startup code)

- STM32L475VGTx_FLASH.ld (liker script)

- jlinkcmd (JLink command script: optional)

Start up code can be found under

demos/st/stm32l475_discovery/common/application_code/st_code

And linker script file can be found under

demos/st/stm32l475_discovery/ac6

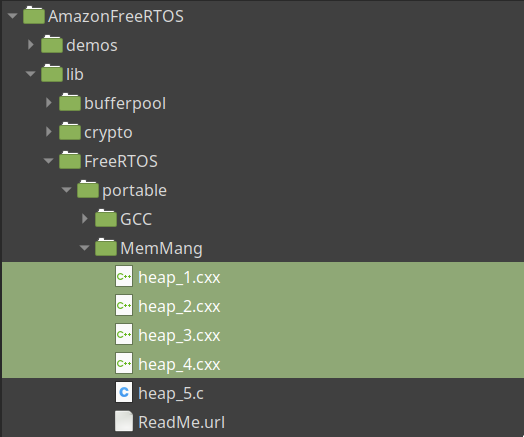

(remove unnecessary files) The source code comes with several files with the same definitions for memory handling, of which you are supposed to link only one file. The Makefile here collects source files automatically by the file extension. Thus you have to remove the unnecessary files from the directory or at least change the file extension. Otherwise you will have conflict definitions. In this case following files need to be removed. You need only heap_5.c.

(change Makefile) Finally, you may need change GCC_PATH variable to match your toolchain setting.